A laser source generates a lot of heat during operation, which must be dissipated in a timely manner, otherwise it may lead to performance degradation or even damage. Therefore, laser welders are equipped with industrial laser cooling systems to ensure their proper functioning. The cooling system is an important part of the laser welding machine, and if it fails, it can lead to serious consequences such as machine downtime or even burnt optics.

What a Laser Chiller Does?

The laser chiller mainly circulates the cooling water through the cooling water tank to reduce the temperature, with constant temperature, constant pressure and constant flow.

Application of Laser Cooling System

Due to the heat generated by lasers source for welding, cutting and punching, the temperature rises and reduces the quality of the beam, thus affecting the processing results. Cooling systems prevent excessive temperatures and allow your laser to maintain excellent productivity.

What Type of Laser Chiller?

Cooling method has an important impact on the performance and application of laser welding machines. Air-cooled and water-cooled are two common cooling methods, each of which has its own advantages and disadvantages and is suitable for different scenarios and needs.

Air-Cooled Chiller

Air-cooled laser welders blow cooling air through the laser components via a fan to absorb and dissipate heat. This system has a relatively simple structure and is relatively easy to maintain and operate. It does not require an additional water source and can effectively cool the laser through natural convection or with the assistance of a fan. For some low-power laser welding applications, air-cooled systems are adequate and relatively more cost-effective.

Laser Water Chiller

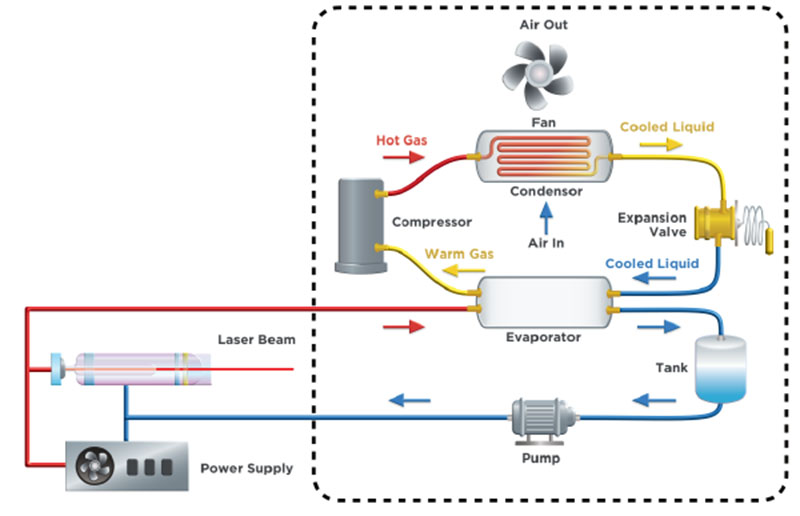

The water laser cooling system is to carry away the heat generated by the laser through the circulating water and to control the temperature of the circulating water within a certain range to ensure the output power and quality of the laser. Water-cooled systems have better cooling effect and can better control the temperature of the laser, which is suitable for high-power laser welding applications. The cooling system generally consists of a water chiller, water tank, water pump, piping and so on. Although a water-cooled system is relatively complex, requiring a water supply and connection to an external water circulation system, it is typically more durable and can provide more consistent performance over long periods of high load operation.

Therefore, the choice between an air-cooled or water-cooled laser welders depend on the specific application requirements and budgetary considerations. For low power requirements and limited budgets, an air-cooled system may be a good choice, while a water-cooled system is more appropriate for high-power laser welding applications or scenarios where stability is important.

How Does a Water Chiller Work?

Filter Function: The chiller is usually equipped with a filter, which is used to effectively filter particulate impurities in the water to keep the laser pump chamber clean and avoid clogging the water circuit.

Water quality selection: The chiller uses pure water or deionized water, which is conducive to the cleanliness of the laser pump cavity and provides better laser beam.

Water pressure monitoring: The chiller is usually equipped with a water pressure gauge, which can visually monitor the water pressure in the laser water circuit to ensure smooth water flow.

Material and cooling effect: the chiller adopts imported compressor to provide stable cooling effect.

Stainless steel material: the water tank, water pump and heat exchange coil are made of stainless steel to ensure the working stability of the chiller.

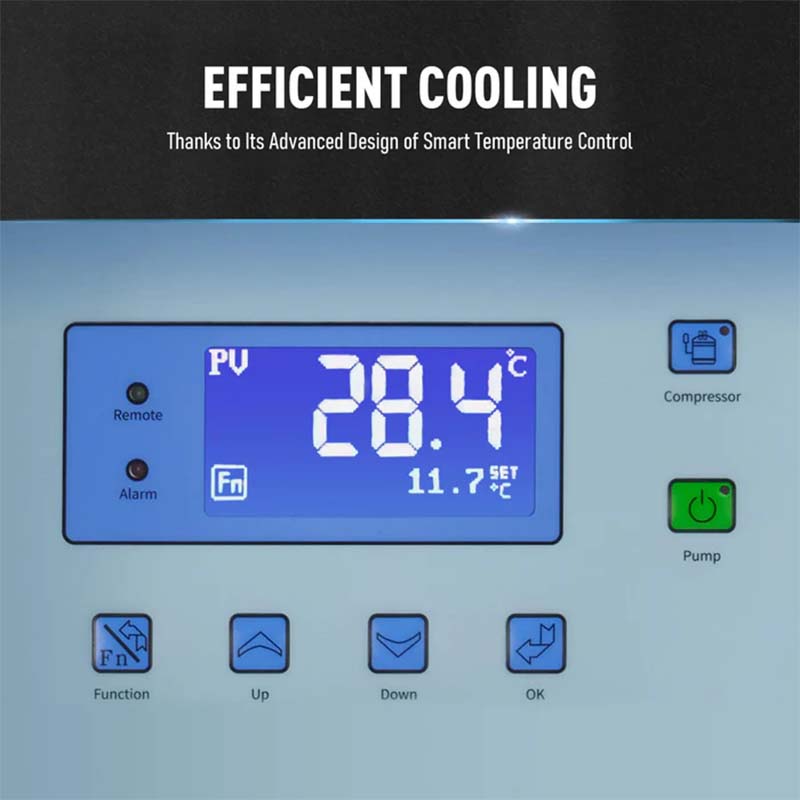

Temperature control: the cooling system can accurately control and display the temperature, and the temperature accuracy reaches within 1℃, so that the laser is less affected by the temperature. Chiller with temperature protection, if the temperature is too high or too low, there will be a signal alarm.

Water quantity protection: when the water flow is less than the set value, there is a signal alarm, which can be used to protect the laser and related devices to dissipate heat.

Chiller for laser welding machine ensures the stable operation and efficient work of laser welding equipment by filtering water quality, monitoring water pressure, using high quality materials and precise temperature control.

Temp. Settings of Chiller for laser welding machine

The temperature range of the chiller for the laser welding machine should be between 5°C and 35°C. Exceeding this range can lead to various issues such as decreased power output, reduced stability, and even equipment damage. A temperature too low may increase energy consumption, raise condensation risk, and affect the circulation of water. Therefore, it is important to closely monitor the operating status and water temperature of the chiller when in use, and make timely adjustments and maintenance. Setting a fixed temperature value is relatively simple, requiring only inputting the desired temperature on the control panel.The Ultimate Guide to Laser Cooling Chillers

Chillers for Welding is designed to ensure proper operation and performance of the laser, extend its service life, and prevent damage and malfunctions.

- Water Flow Control: The laser welding process requires a continuous supply of sufficient cooling water to maintain welding stability and results. Therefore, water flow control is required when configuring the chiller. It is usually recommended to use a combination of turbine flow meter and doubling clutch, which can automatically adjust the water flow according to the laser power, welding time and other parameters to ensure the stability of water flow.

- Cooling water quality and quantity: Pure or deionized water should be used and kept clean to avoid contamination. At the same time, ensure that sufficient water is provided to maintain the flow and pressure of the circulating water to prevent interruptions or blockages.

Types of fluids added to laser chillers

Distilled water

Distilled water is also free of impurities and will not rust with surrounding parts. Distilled water is recommended as a coolant for laser chillers.

Pure Water

Purified water contains more minerals than distilled water and is more conductive. Over time, the minerals in purified water will accelerate the corrosion of laser chiller accessories.

Tap water

Calcium and magnesium minerals in tap water and chemicals accelerate corrosion of tank accessories. Over time, scale build-up can clog water pipes and cause the laser cooler to stop working.

- Regular Replacement and Cleaning: If you use distilled water, it is recommended to replace the liquid and clean the water tank every 2-3 months. Use dedicated cleaning agents to avoid corrosive substances.

- Adjusting Water Temperature: To ensure the stability and effectiveness of laser welding, the cooling water temperature generally needs to be controlled between 20-25°C. When configuring the chiller, choose one with intelligent temperature control, allowing for temperature adjustments as needed to achieve optimal results.

- Operation and Maintenance of Cooling System: Start the cooling system before turning on the laser and shut it off afterward. Regularly check the operation status and parameters of the chiller, such as temperature, flow rate, and pressure of the circulating water, and perform timely adjustments and maintenance. Immediately shut down and troubleshoot in case of any abnormal findings.

Winter Maintenance Tips for Industrial Laser Cooling Systems

In low-temperature environments, it is recommended to preheat the entire machine for 20 minutes before starting.

- Maintain continuous operation of the chiller: In areas where power outages are rare, it is advisable to keep the industrial chiller running continuously. Additionally, set both the ultra-low temperature water and normal temperature water to around 5°C to ensure that the temperature of the cooling circulating water is above the condensation point of the chiller, thereby saving energy.

- Drain the water tank and pipelines when the machine is shut down for a long time.

- Use antifreeze instead of cooling circulating water: If power outages are frequent in the natural environment or it is not feasible to empty the cooling circulating water daily, antifreeze should be used instead.

These maintenance measures ensure the normal operation of laser welding equipment in winter, prolong the equipment’s lifespan, and guarantee production efficiency and quality.

How to Choose the Handheld Laser Welding Chiller

DPLaser deeply understands that an efficient cooling system is essential to ensure the long-term stable operation of laser equipment and optimize processing performance. Therefore, we carefully equip each laser welding machine with a high-performance water cooler, designed to provide continuous and stable cooling guarantee for your production process.

Features of Water Cooling System for Laser Handheld Welding Machine

- Intelligent control system: equipped with microcomputer intelligent control, automatically adjust the cooling water flow and temperature, adapt to the real-time working conditions of the laser equipment, and support unattended automated operation.

- High-efficiency water filtration system: the built-in water filter effectively removes impurities in the circulating water, prevents pipeline clogging, and enhances the safety of laser equipment operation.

- High-performance refrigeration components: Hitachi original imported compressor to ensure efficient and stable refrigeration effect, and through the special control panel to achieve ±0.1℃ high-precision temperature control, to protect the high precision and stability of laser processing.

- Precision temperature control technology: applying advanced temperature control technology, even in high-intensity continuous operation, it can accurately maintain the optimal working temperature of the laser and improve the processing quality.

- Flow rate and safety protection: Intelligent flow rate monitoring function, automatic shutdown to protect the compressor when the flow rate is low, as well as overheating and water flow abnormality alarm system, double guarantee the safety of laser equipment.

- Convenient maintenance design: key components such as filters and heat exchangers are designed to be easy to disassemble and clean, which promotes the cleanliness of the water circulation system, effectively resists limescale and prolongs the service life of the equipment.

- Wide applicability: suitable for a variety of power laser welding and cutting machines, whether precision processing or heavy industrial scenarios, Roc laser water cooler can provide customized cooling solutions to meet different needs.

Choosing DPLASER handheld laser welding chiller means more than just selecting a piece of equipment. It’s partnering with a 16-year seasoned expert team in the field. We’ve cultivated rich experience and professional knowledge in the laser domain, mastering every detail of laser cutting, welding, and marking machines. Thus, DPLaser not only focuses on the development of laser welding machines, marking machines, and cutting machines but also strives to provide optimized solutions for laser application.

We offer isn’t just components, it’s a meticulously designed and rigorously tested system aimed at elevating the efficiency and precision of your laser cutting or welding fabrication.