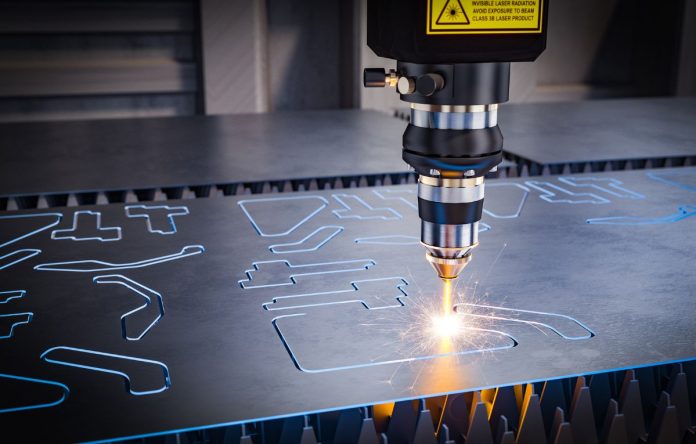

In the world of industrial manufacturing, laser marking has become an integral process for product identification, branding, and traceability. Laser marking machines are widely used to etch permanent markings on a variety of materials, including metals, plastics, and ceramics. However, achieving optimal laser marking quality, resolution, and cleaning effectiveness requires careful consideration of several factors. In this blog post, we’ll delve into these crucial elements to help you maximize the performance of your laser marking operations.

Material Properties

The first factor to consider is the nature of the material being marked. Different materials have varying levels of absorbance, reflectivity, and thermal conductivity, which can significantly impact the quality and resolution of the laser marking. For instance, highly reflective materials like aluminum or stainless steel may require higher laser power or specific wavelengths to achieve clear and crisp markings. On the other hand, materials with low thermal conductivity, such as certain plastics, may be more susceptible to heat damage, potentially compromising the mark quality.

When it comes to laser welding machines, their ability to fuse materials together with precision and strength is equally dependent on factors like material composition, joint design, and process parameters. However, in this post, we’ll primarily focus on the factors affecting laser marking quality, resolution, and cleaning effectiveness.

Laser Parameters

Laser power and speed are two critical parameters that significantly influence the marking quality and resolution. Higher laser power generally results in deeper and more well-defined markings, but it can also increase the risk of material damage or distortion. Conversely, lower laser power may produce shallower marks with reduced contrast. The marking speed also plays a crucial role, as slower speeds allow for more energy absorption, leading to deeper marks, while faster speeds may result in shallower or inconsistent markings.

Optics and Lens Configuration

The lens configuration and focal distance of the laser marking system can also impact the resolution and clarity of the markings. A well-designed and properly aligned lens system ensures that the laser beam is focused precisely on the target surface, resulting in sharper and more detailed markings. Conversely, a poorly aligned or unsuitable lens configuration can lead to blurred or distorted markings.

Environmental Factors

Another factor to consider is the marking environment. Factors such as ambient temperature, humidity, and the presence of contaminants can affect the laser marking process. For example, high humidity levels can cause condensation on the lens or target surface, potentially distorting the laser beam and compromising the marking quality. Similarly, the presence of dust or debris can scatter the laser beam, reducing its effectiveness and potentially causing defects in the markings.

Surface Preparation and Cleaning Effectiveness

Surface preparation is a crucial step in achieving optimal laser marking quality and cleaning effectiveness. The target surface should be free from contaminants, such as oils, greases, or dirt, as these can interfere with the laser beam’s ability to interact with the material effectively. Proper cleaning and surface preparation techniques, such as degreasing or abrasive blasting, can significantly improve the marking quality and ensure that the markings are crisp, clear, and durable.

After the laser marking process, cleaning the marked surface is equally important to maintain the quality and legibility of the markings. Depending on the material and the marking process, various cleaning methods can be employed, including mechanical cleaning (e.g., brushing or sandblasting), chemical cleaning (e.g., solvents or acids), or a combination of both.

It’s important to note that the cleaning method should be carefully selected and applied to avoid damaging or altering the markings. For instance, aggressive mechanical cleaning techniques may inadvertently remove or distort the markings, while improper chemical cleaning can cause corrosion or discoloration of the material.

Maintenance and Calibration

Regular maintenance and calibration of the laser marking system are essential for maintaining consistent marking quality and resolution over time. Laser sources, optics, and other components can degrade or become misaligned due to various factors, such as wear and tear, temperature fluctuations, or vibrations.

Scheduled maintenance checks and calibration procedures help ensure that the laser beam is accurately focused and aligned, and that the marking parameters are optimized for the specific material and application. Neglecting maintenance and calibration can lead to gradual deterioration of marking quality, decreased resolution, and potential downtime due to equipment failures.

Operator Training and Process Control

While technological factors play a significant role in laser marking quality, resolution, and cleaning effectiveness, human factors should not be overlooked. Proper operator training and adherence to established processes and protocols are crucial for achieving consistent and reliable results.

Operators should be thoroughly trained on the operation, maintenance, and safety aspects of the laser marking system. They should understand the impact of various parameters, such as laser power, speed, and lens configuration, on the marking quality and resolution. Additionally, they should be familiar with the appropriate surface preparation and cleaning techniques for the specific materials being marked.

Implementing robust process control measures, such as standard operating procedures (SOPs), quality checks, and documentation, can help ensure consistent marking quality and minimize variations due to human error or deviations from established practices.

Continuous Improvement and Innovation

Finally, it’s essential to embrace a mindset of continuous improvement and innovation in the laser marking industry. As new materials, technologies, and applications emerge, the factors affecting laser marking quality, resolution, and cleaning effectiveness may evolve.

Staying up-to-date with the latest advancements in laser technology, material science, and process optimization techniques can help manufacturers stay ahead of the curve and adapt to changing market demands. Collaboration with industry experts, research institutions, and equipment manufacturers can provide valuable insights and enable the development of innovative solutions to address emerging challenges.

By continuously evaluating and improving the factors influencing laser marking quality, resolution, and cleaning effectiveness, manufacturers can ensure that their products meet the highest standards of quality, durability, and traceability, while improving operational efficiency and reducing costs.

Conclusion

In conclusion, achieving optimal laser marking quality, resolution, and cleaning effectiveness requires a holistic approach that considers factors such as material properties, laser parameters, surface preparation, maintenance, operator training, and continuous improvement. By carefully managing and optimizing these factors, along with utilizing effective laser cleaners, manufacturers can unlock the full potential of laser marking technology and deliver products that meet the highest standards of quality and traceability.